概述

ZA/KJW型电动调节蝶阀由DKJ角行程电动执行机构和蝶阀组成,它与电动单元组合仪表配合使。具有结构简单、口径大、重量轻、操作方便等优点。广泛应用于冶金、电站石油、化工等部门。

规格与技术参数

|

公称通径mm

|

50

|

80

|

100

|

125

|

150

|

200

|

250

|

300

|

350

|

400

|

450

|

500

|

600

|

700

|

800

|

1000

|

1200

|

1400

|

1600

|

1800

|

1900

|

2000

|

|

额定流量系数KV

|

85

|

225

|

340

|

500

|

770

|

1360

|

2130

|

3060

|

4160

|

5450

|

6900

|

8500

|

12200

|

16600

|

21700

|

34000

|

49000

|

66600

|

87000

|

110000

|

123000

|

136000

|

|

执行机构型号

|

DKJ

|

|

公称压力Mpa

|

0.6

|

|

介质温工

|

常温:-20~200(铸铁) -40~250(铸钢) 中温-40~450(铸不锈钢)

|

|

转角范围

|

平行闸版0~70° 倾斜阀板0~60°

|

|

流量特性

|

近似等百分比

|

|

接管法兰

|

按JB78-59中对夹式法兰连接

|

|

动作时间S

|

25

|

|

阀体材质

|

HT200 35 ZG230-450

1Cr18Ni9 ZG1Cr18Ni9Ti ZG1Cr18Ni12Mo2Ti

|

执行机构主要技术参数

|

型号

|

DKJ-110

|

DKJ-210

|

DKJ-310

|

DKJ-410

|

DKJ-510

|

|

输入信号

|

DC0-10mA DC4-20mA

|

|

输入电阻

|

200

|

|

输出转角

|

0~90

|

|

输出矩力N.m

|

40

|

100

|

250

|

600

|

1600

|

|

电源

|

200V 50HZ

|

主要技术性能指标

|

项目

|

指标值

|

|

基本误差%

|

±8.0

|

|

回差%

|

6.0

|

|

死区%

|

5.0

|

|

额定行程偏差%

|

±4.0

|

|

允许泄漏量L/h

|

平行阀板:2×10-2阀的额定容量,倾斜滑板:5×10-3阀的额定容量

|

允许压差与执行机构选型

|

公称通径mm

|

配用执行机构

|

|

DKJ-110

|

DKJ-210

|

DKJ-310

|

DKJ-410

|

DKJ-510

|

DKJ-610

|

|

0°

|

70°

|

0°

|

70°

|

0°

|

70°

|

0°

|

70°

|

0°

|

70°

|

0°

|

70°

|

|

50

|

28.1

|

1.948

|

|

|

|

|

|

|

|

|

|

|

|

50

|

11.0

|

0.488

|

|

|

|

|

|

|

|

|

|

|

|

100

|

7.127

|

0.252

|

|

|

|

|

|

|

|

|

|

|

|

125

|

3.19

|

0.128

|

8.08

|

0.325

|

|

|

|

|

|

|

|

|

|

150

|

2.21

|

0.075

|

5.6

|

0.189

|

|

|

|

|

|

|

|

|

|

200

|

0.983

|

0.031

|

2.512

|

0.079

|

|

|

|

|

|

|

|

|

|

250

|

|

|

|

|

4.05

|

0.103

|

|

|

|

|

|

|

|

300

|

|

|

|

|

2.33

|

0.059

|

|

|

|

|

|

|

|

350

|

|

|

|

|

1.75

|

0.037

|

|

|

|

|

|

|

|

400

|

|

|

|

|

|

|

2.684

|

0.060

|

|

|

|

|

|

450

|

|

|

|

|

|

|

2.120

|

0.042

|

|

|

|

|

|

500

|

|

|

|

|

|

|

1.718

|

0.031

|

|

|

|

|

|

600

|

|

|

|

|

|

|

0.927

|

0.0178

|

|

|

|

|

|

700

|

|

|

|

|

|

|

0.628

|

0.0098

|

|

|

|

|

|

800

|

|

|

|

|

|

|

|

|

1.14

|

0.020

|

|

|

|

1000

|

|

|

|

|

|

|

|

|

0.619

|

0.0103

|

|

|

|

1200

|

|

|

|

|

|

|

|

|

|

|

0.504

|

0.016

|

|

1400

|

|

|

|

|

|

|

|

|

|

|

0.371

|

0.0106

|

|

1600

|

|

|

|

|

|

|

|

|

|

|

0.251

|

0.0076

|

|

1800

|

|

|

|

|

|

|

|

|

|

|

0.177

|

0.005

|

|

1900

|

|

|

|

|

|

|

|

|

|

|

0.151

|

0.0042

|

|

2000

|

|

|

|

|

|

|

|

|

|

|

0.129

|

0.0036

|

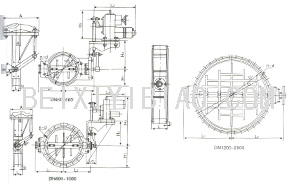

外形尺寸

|

公称通径

|

D

|

D1

|

A

|

e

|

b

|

L

|

L1

|

L2

|

L3

|

H1

|

H2

|

H3

|

n-d

|

配执行机构

|

|

50

|

|

110

|

245

|

30

|

|

60

|

92

|

139

|

357

|

55

|

299

|

270

|

4-14

|

DKJ-210

|

|

50

|

125

|

150

|

245

|

30

|

|

60

|

92

|

139

|

357

|

62.5

|

299

|

270

|

4-18

|

DKJ-210

|

|

100

|

145

|

175

|

245

|

30

|

12

|

60

|

102

|

149

|

357

|

72.5

|

299

|

270

|

4-18

|

DKJ-210

|

|

125

|

175

|

200

|

245

|

30

|

12

|

60

|

117

|

168

|

357

|

87.5

|

299

|

270

|

8-18

|

DKJ-210

|

|

150

|

200

|

225

|

245

|

30

|

12

|

60

|

130

|

181

|

357

|

100

|

299

|

270

|

8-18

|

DKJ-210

|

|

200

|

255

|

280

|

245

|

30

|

12

|

70

|

172

|

221

|

357

|

127.5

|

299

|

270

|

8-18

|

DKJ-210

|

|

250

|

310

|

335

|

300

|

36

|

14

|

70

|

197

|

258

|

507

|

155

|

340

|

298

|

12-18

|

DKJ-310

|

|

300

|

362

|

395

|

300

|

36

|

14

|

80

|

227

|

283

|

507

|

181

|

340

|

298

|

12-23

|

DKJ-310

|

|

350

|

412

|

445

|

300

|

36

|

14

|

80

|

252

|

290

|

507

|

206

|

340

|

298

|

12-23

|

DKJ-310

|

|

400

|

462

|

495

|

365

|

45

|

16

|

100

|

296

|

348

|

529

|

231

|

400

|

381

|

16-23

|

DKJ-410

|

|

450

|

518

|

550

|

365

|

45

|

16

|

100

|

321

|

371

|

529

|

259

|

400

|

381

|

16-23

|

DKJ-410

|

|

500

|

558

|

600

|

365

|

45

|

16

|

100

|

346

|

396

|

529

|

284

|

400

|

381

|

16-23

|

DKJ-410

|

|

600

|

755

|

706

|

365

|

45

|

30

|

150

|

480

|

418

|

530

|

377.5

|

863

|

482

|

20-25

|

DKJ-410

|

|

700

|

860

|

810

|

365

|

45

|

32

|

150

|

530

|

531

|

530

|

430

|

863

|

482

|

24-25

|

DKJ-410

|

|

800

|

975

|

920

|

420

|

51

|

34

|

200

|

595

|

586

|

681

|

487.5

|

917

|

480

|

24-30

|

DKJ-510

|

|

1000

|

1175

|

1120

|

420

|

51

|

36

|

200

|

735

|

721

|

681

|

587.5

|

917

|

480

|

28-30

|

DKJ-510

|

|

1200

|

1400

|

1340

|

|

60

|

45

|

250

|

906

|

980

|

|

|

|

|

32-34

|

DKJ-610

|

|

1400

|

1575

|

1520

|

|

60

|

25

|

300

|

956

|

1012

|

|

|

|

|

36-30

|

DKJ-610

|

|

1600

|

1785

|

1730

|

|

60

|

25

|

350

|

1065

|

1112

|

|

|

|

|

40-30

|

DKJ-610

|

|

1800

|

|

|

|

|

|

|

|

|

|

|

|

|

|

DKJ-610

|

|

1900

|

2100

|

|

|

|

25

|

350

|

1217

|

1315

|

|

|

|

|

44-30

|

DKJ-610

|

|

2000

|

|

|

|

|

|

|

|

|

|

|

|

|

|

DKJ-610

|

技术参数如有更改,恕不另行通知

订货须知

1、产品型号 2、公称通径 3、公称压力 4、阀体和阀内件材质 5、转角范围 6、作用方式 7、介质温度 8、输入信号 9、附件

|